Some heat transfer material emits toxic fumes. But the question today is can you laser cut vinyl? Let’s take a look at laser-safe vinyl.

There is so much misinformation floating around about laser-cutting heat transfer vinyl. Some heat transfer material emits toxic fumes.

Some HTV polyvinyl chloride or PVC products contain pulmonary irritants such as toxic chlorine gas and hydrochloric acid.

Can You Laser Cut Vinyl?

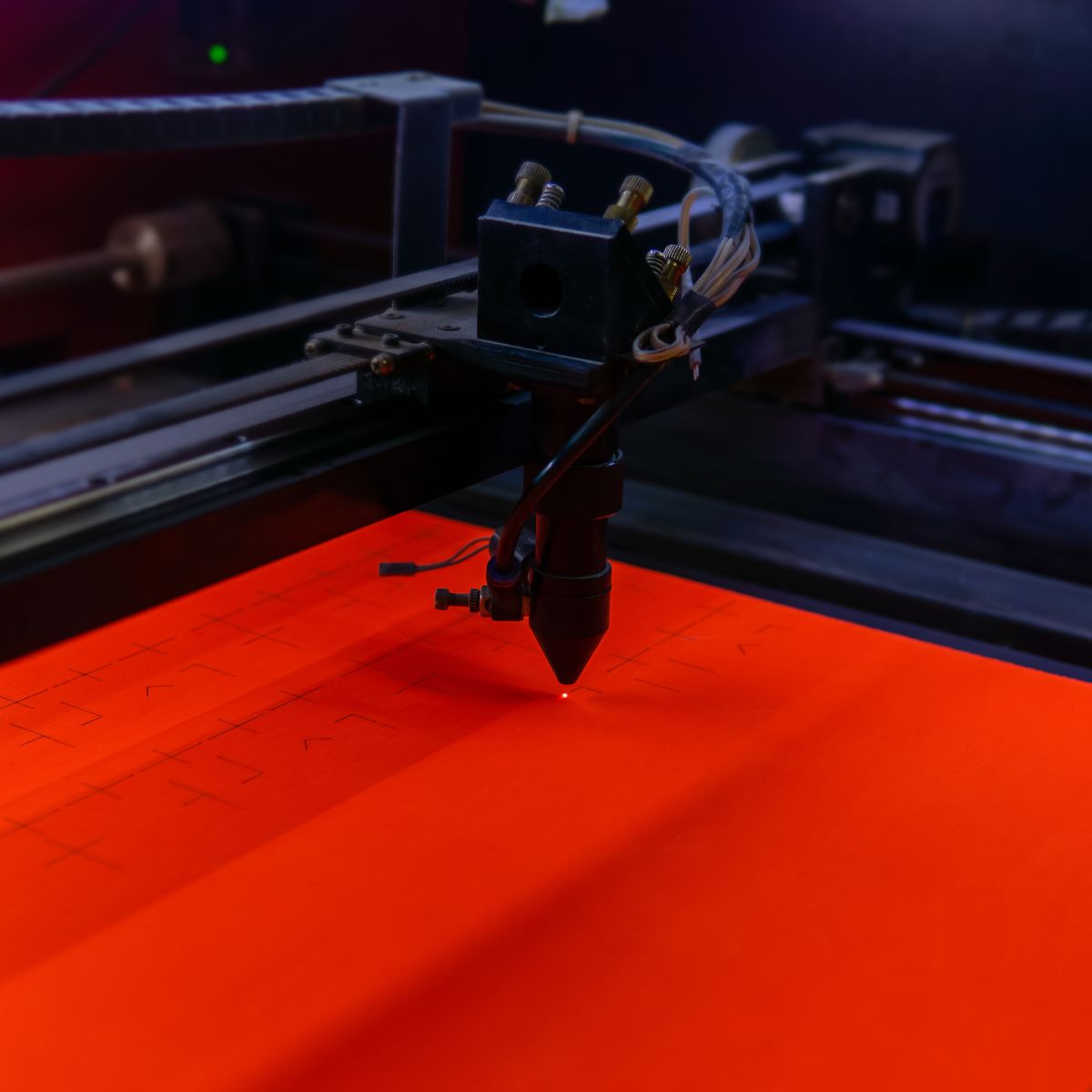

Vinyl is not a common material for cutting with a laser. But wouldn’t it be awesome to use the laser beam to achieve the most complex designs?

So, can you laser-cut vinyl? The short answer to this question is yes! If you only have a CO2 laser machine and no vinyl cutter there is laser-safe vinyl out there for you to use. The bad news just grabbing any vinyl and assuming that you can use it in your laser cutter is a poor choice. The good news is that there is a safe way to use the power of your laser to get those precise cuts using the power of the laser.

There are a few things you need to know before you get started. Let’s take a second and talk about the basics of laser cutting standard vinyl and get you some great tips for getting the best results. We will also take a look at some of the best vinyl materials for laser cutting so you get started right.

Choosing the Right Vinyl

One of the most important things to know about laser cutting vinyl is that not all types of vinyl are the same. Meaning some types of vinyl as I mentioned above contain PVC which is dangerous and also toxic and is a health hazard. Or they can cause environmental hazards

If you are planning on using a laser cutter to cut your vinyl, it is important to choose a material that is laser safe and doesn’t pose any health hazards that comes with cutting plastic material.

To avoid the fumes associated with using your laser engraver to cut heat-transfer vinyl materials, you are going to want to look for a PVC-free heat-transfer product.

Best Vinyl Brands for Laser Cutting

Some of my favorite brands of vinyl for cutting with a laser cutter are Siser (everything from Easyweed to all their other lines are laser-cut-friendly) and Avery Dennison vinyl. These brands all offer a variety of colors and finishes, so you can find the perfect material for your project. In addition, they are all relatively easy to cut with a laser cutter.

Let’s dig deeper into each one and see what we can find out!

What Brands Can You Use With The Laser?

Siser has the most extensive variety of vinyl that you can use in your laser. Also available are.

This is another great all-purpose vinyl that can be used for a variety of projects. It also cuts well with a laser cutter and can be used indoors or outdoors.

This vinyl is a bit thicker than Oracal 651, which is NOT laser-safe, so it is a better choice if you are new to working with vinyl. It is also less likely to warp or distort when cut with a laser cutter. Avery offers a wide range of vinyl products, from their economy line to their premium cast vinyl. Their cast vinyl is especially well-suited for laser cutting, and they come in a variety of finishes, including gloss, matte, and brushed metal.

I’m sure that there are other brands that are laser-ready, but before you just grab something off the shelf, be sure to look up that specific brand first. No sense in getting it back to your craft space and being disappointed!

Additional Considerations With Cutting Vinyl Using a Laser Cutter

If you are new to vinyl cutting with a laser, I would recommend starting with a simple project. For example, you could create a custom vinyl decal for your car or laptop.

Once you have mastered the basics of cutting vinyl, you can move on to more complex projects like creating signs and banners.

Some of my favorite project ideas for beginners include:

- Cutting vinyl letters or shapes to create a custom decal

- Making a sign for your business or home

- Creating labels for storage containers or jars

- Tossing together a vinyl shirt design for the kids

The sky is the limit when it comes to cutting vinyl with a laser cutter. Once you understand the basics, you can let your imagination run wild!

Tips for using the Laser And Vinyl

Now that you know the basics of laser cutting vinyl, let’s take a look at some tips for getting great results whether it’s your first project or your 900th.

First, always test your settings on scrap material before cutting your project piece. This will help you to determine the best power and speed settings for your particular vinyl and cutter. If you’re using a material and settings you’ve used time and again, but just starting a new roll of vinyl, I even recommend using a bit of scrap from the same roll to test, that way if the material varies at all in any way, you can make appropriate adjustments.

Second, when cutting intricate designs, it is often helpful to use multiple passes at lower power settings. This will prevent the vinyl from warping or distorting as you cut. Take care to let the vinyl cool completely between passes, too. No sense in speeding through just to get a wonky result.

I like to be sure to use a cutting mat when working with vinyl. This will protect your work surface and help to keep the vinyl in place as you cut. Nothing is more frustrating than a little gust of wind pushing your design off by a hair and messing everything up.

Try to weed your vinyl designs immediately after cutting. This will make the wedding process much easier and prevent any unwanted pieces from sticking to your design. I don’t know if the vinyl just has this self-healing thing or if it’s just me, but vinyl just seems to weed better right after cutting – particularly when using the laser.

Finally, take your time! Vinyl cutting is not a race. If you rush, you are more likely to make mistakes. So just relax and enjoy the process.

Now that you know everything you need to about laser cutting vinyl, it’s time to get started on your next project! Just remember to take your time, test your settings, and choose the right vinyl for your needs. With a little practice, you’ll be an expert in no time!

If you are just checking into your options for laser cutters you can read Glowforge VS Cricut A 2022 Ultimate Comparison and for information on Glowforge check out Glowforge Overview: What to Know Before You Buy